Candle making may seem like a simple process, but it can be fraught with mistakes that affect the quality of the final product. Whether you're a beginner or a pro, you might encounter problems at some stage of candle making, such as choosing the wick, controlling the temperature, or storing the candles correctly. In this article, we'll review common candle-making mistakes and how you can avoid them to ensure you get candles that are perfect in terms of appearance, fragrance, and quality.

1. Choosing the wrong wick

A. The problem

The wick is one of the most important elements in candle making, as it directly affects the candle's burning. Choosing a wick that is too small results in a "tunnel" in the center of the candle, where the wax melts only around the wick, leaving the edges unburned. Conversely, choosing a wick that is too large leads to rapid burning and black smoke.

B. Solution

Make sure you choose the right wick for the size of the candle and the type of wax you're using. Each type of wax has specific requirements that necessitate a particular wick, so consult your wax supplier's wick charts to determine the appropriate size.

2. Lack of control over the wax temperature

A. The problem

Melting wax at very high temperatures causes essential oils to evaporate quickly and lose their fragrance. The wax may also change color or produce smoke during burning. Conversely, melting wax at low temperatures can cause lumps and an uneven consistency.

B. Solution

Place the wax in a double boiler and heat it slowly until it reaches the appropriate temperature for the type of wax used. If using essential oils, add them when the wax temperature drops to approximately 70-75°C to prevent the fragrance from evaporating.

3. Add plenty of essential oil

A. The problem

Adding excessive amounts of essential oil can result in an unstable candle, where the candle becomes too soft and may not burn properly. Excess essential oils can also cause unstable burning and excessive smoke.

B. Solution

Follow the optimal ratio for adding essential oils, which is usually between 6-10% of the wax weight. Choose oils specifically formulated for candle making, as they are more compatible with the wax and help maintain the fragrance while burning.

4. Not waiting for the wax to cool properly

A. The problem

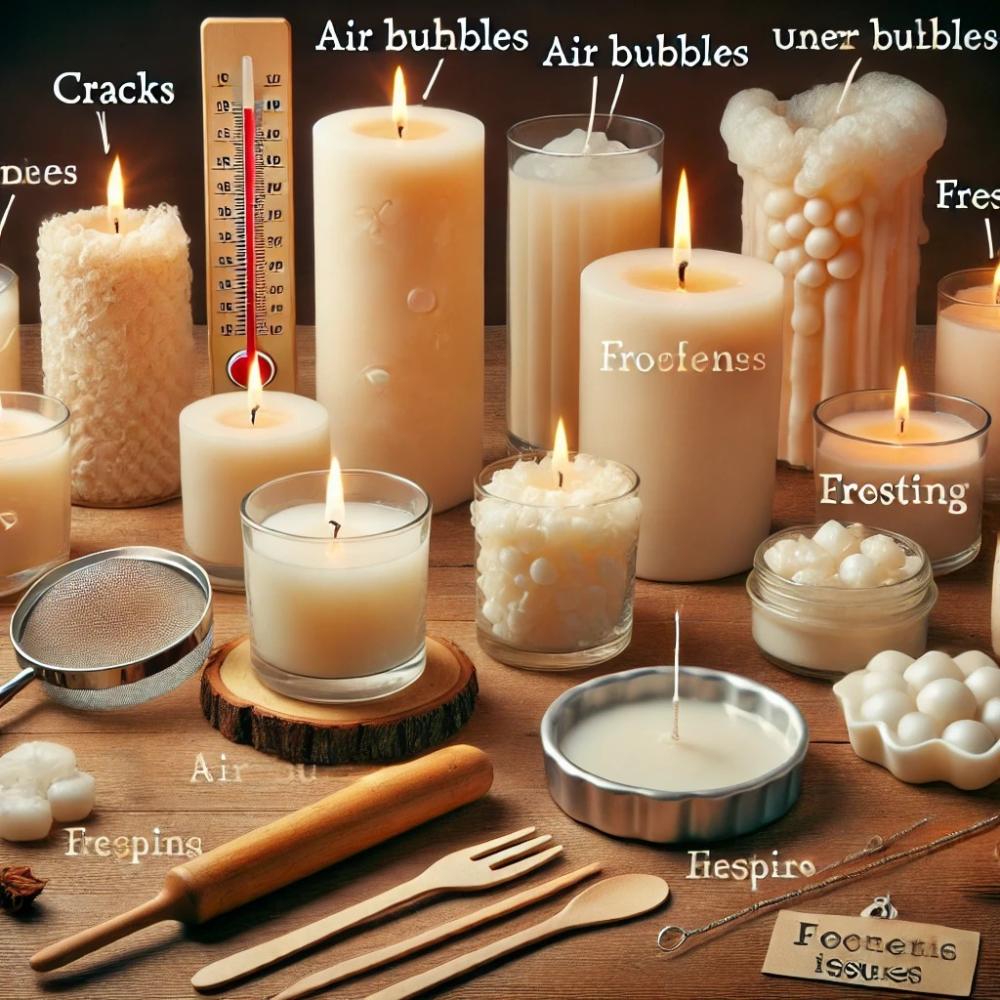

Pouring wax when it's too hot or allowing it to cool too quickly can cause air bubbles or cracks to form on the candle's surface. These imperfections affect the candle's final appearance and may result in uneven burning.

B. Solution

After pouring the wax into the mold, allow it to cool slowly at room temperature. Avoid exposing the filled candles to cold drafts or high temperatures, as this may affect the candle's structure.

5. Failure to prepare the molds correctly

A. The problem

Failure to properly secure the wick in the mold or to clean the mold before pouring the wax may lead to problems in the burning process, such as wick deviation or the appearance of unwanted air bubbles.

B. Solution

Before pouring the wax, make sure the mold is thoroughly cleaned to ensure the wax adheres properly. Also, secure the wick in the center of the mold using a base or tape to ensure it remains straight and stable during the cooling process.

6. Failure to test the candle before selling

A. The problem

Failure to test candles before selling them may lead to the discovery of later defects such as uneven burning or smell problems, affecting the user experience.

B. Solution

Be sure to test each batch of candles before offering them to customers. Allow the candle to cool for 24-48 hours, then light it to observe the burning behavior and assess the fragrance. If you notice any problems, adjust the recipe or wick before commencing mass production.

7. Not storing candles properly

A. The problem

Storing candles in an unsuitable environment may affect their quality, as candles can be affected by heat or humidity, leading to a change in shape or loss of fragrance.

B. Solution

Store candles in a cool, dry place away from direct sunlight or heat sources. Make sure to cover them with airtight lids to preserve the fragrance and prevent exposure to air and moisture.

Conclusion

Candle making requires precision and attention to detail, as even small mistakes can affect the quality of the final candle. By avoiding common errors such as choosing the wrong wick, failing to control the temperature, or storing candles improperly, you can improve candle quality and create a perfect product that pleases your customers and enhances your reputation in the market.