When making candles, you might encounter wax shrinkage, one of the most common problems affecting candle quality and appearance. Wax shrinkage occurs when the wax contracts as it cools, resulting in unwanted gaps or wrinkles on the candle's surface or around the wick. In this article, we'll explore common causes of wax shrinkage and practical solutions to avoid this problem and achieve perfect candles.

1. What is wax shrinkage?

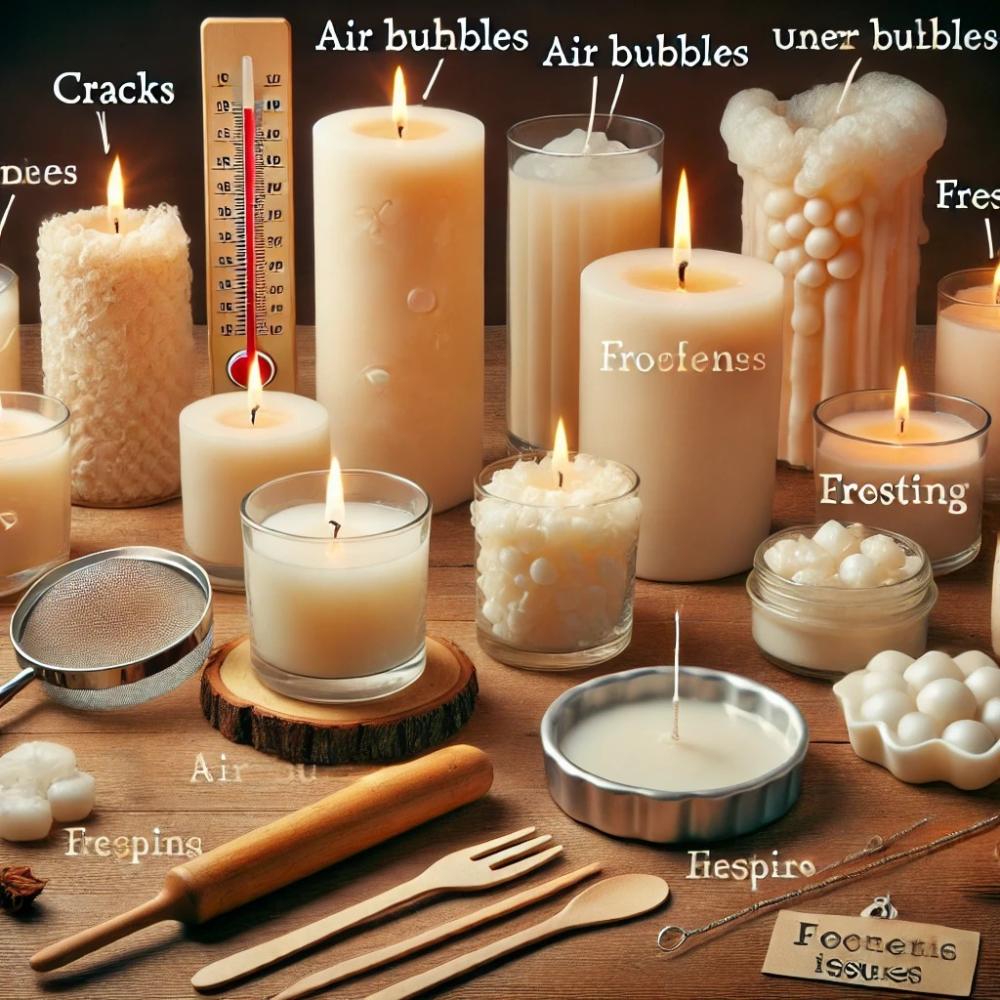

Wax shrinkage is a natural process that occurs when wax cools after being poured. Some types of wax expand when heated and contract when cooled, resulting in gaps or cracks on the candle's surface or around the wick. This problem affects the candle's appearance and reduces its quality.

2. Common causes of wax shrinkage

a. High temperature when pouring wax

One of the main reasons for wax shrinkage is pouring the wax at a very high temperature. When wax is overheated and then poured into the mold, it shrinks rapidly upon cooling, resulting in wrinkles and distortions.

b. Rapid cooling

Rapid cooling is another common cause of wax shrinkage. When a candle cools too quickly, especially if the molds are in a very cold environment, the wax shrinks rapidly, causing gaps to form around the wick or on the surface.

c. Type of wax used

Some types of wax are more prone to shrinkage than others, such as paraffin wax, which tends to shrink when cooled. In contrast, soy wax or beeswax may shrink to a lesser extent.

3. How to deal with wax shrinkage problems

A. Adjusting the casting temperature

Avoid heating the wax to excessively high temperatures. It's best to pour the wax at a lower temperature, between 65-75°C, depending on the type of wax used. Each type of wax has a specific optimal temperature, so be sure to read the manufacturer's recommendations.

- Tip : If you notice that the wax is shrinking continuously, try gradually reducing the pouring temperature until you get better results.

b. Controlling the cooling process

Avoid exposing candles to sudden cold temperatures. Allow them to cool slowly at room temperature. You can cover the mold with a cloth or towel to slow down the cooling process.

- Tip : Keep the molds away from cooling sources such as fans or air conditioners. Gradual cooling reduces the chances of shrinkage.

c. Choosing the right wax

If you're experiencing frequent shrinkage, try changing the type of wax. Soy wax and beeswax are less prone to shrinkage than paraffin wax.

- Tip : Choose the right type of wax for your product. If you're making large candles or molded candles, choose a wax known for shrinking less when cooled.

4. Repairing Shrinking Candles

If the candles you made are shrinking after cooling, there are some easy solutions to fix them:

a. Add an additional layer of wax

To repair gaps caused by shrinkage, you can heat a small amount of wax and pour it over the damaged candle. This extra layer will cover the gaps and give the candle an even appearance.

- Tip : Make sure the additional wax layer is at a slightly lower temperature to avoid further shrinkage.

b. Surface heating

You can use a heat gun or hair dryer to gently heat the surface of the candle. When the surface is heated, the wax will even out and eliminate wrinkles or small gaps.

- Tip : Use low heat and avoid overheating to prevent the candle from melting completely.

5. Additional tips to avoid wax shrinkage

a. Use of wax additives

You can add additives to the wax such as citric acid or zinc stearate , which help to reduce shrinkage and improve the wax's stability when cooling.

b. Avoid filling the templates completely.

When pouring the wax, leave a small gap at the top edge of the mold to avoid excessive pressure that could cause unwanted shrinkage when cooling.

c. Prepare the molds properly

Make sure the molds are clean and completely dry before pouring the wax. The presence of moisture may increase the likelihood of shrinkage or cracking.

Conclusion

Wax shrinkage is a common problem that can be avoided by following the right tips. By controlling the pouring temperature and cooling gradually, and choosing the right type of wax, you can prevent candle shrinkage and achieve a high-quality finished product. By following these practical solutions, you can improve your candle-making process and ensure your customers are satisfied with every candle you make.